Jointer Coupling

$ / ₹

A coupling is a mechanism that connects two shafts at their ends in order to transmit Power. They also hep in incorporate overload protection. In the event of space constraints, to add further flexibility while transmitting power. Also, to reduce jerk loads while roation of shafts.

Couplings are categorized into two types: material flexing and mechanical flexing. Mechanical flexing connections accommodate misalignment caused by metal surface shaking, rolling, or sliding. Lubrication is required for all metal mechanical flexing connections.

Roller Chain Coupling :

Torque is transmitted through the intertwining of the sprocket teeth and chain, and the accompanying clearances allow for angular, parallel, and axial misalignment.

Depending on the use, chain couplings require periodic lubrication. Lubricant is usually dusted onto the chain, and a cover is utilised to maintain the lubricant on the coupling.

Flange coupling:

Flanges are present on both sides of the two sleeves in this case. Both flanges are made up of an equal number of threaded holes for fastening. Bolts and nuts are then used to connect the flanges. On the hub and shafts, a key area is also supplied to prevent slippage.

In this case, a tapered key is employed. This prevents the hub from loosening or moving rearward and keeps it fixed to the shafts.

Flange couplings are utilised in medium and heavy-duty industrial applications.

Jaw Coupling:

The jaw coupling transmit power with the help of an elastomeric spring positioned between two intermeshing jaws. The spring ffer a high burden limit while keeping a damping impact on vibration and thermal properties.The elastomer material gives great protection from oils and synthetic substances.

At the point when the spider fails, the coupling's safeguard configuration becomes an integral factor. The jaw structure will interlock and continue the operation, giving enough time to shut down the system without harming machinery.

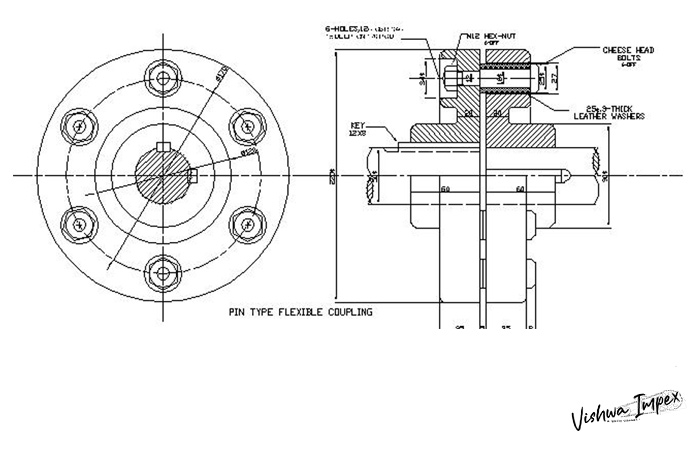

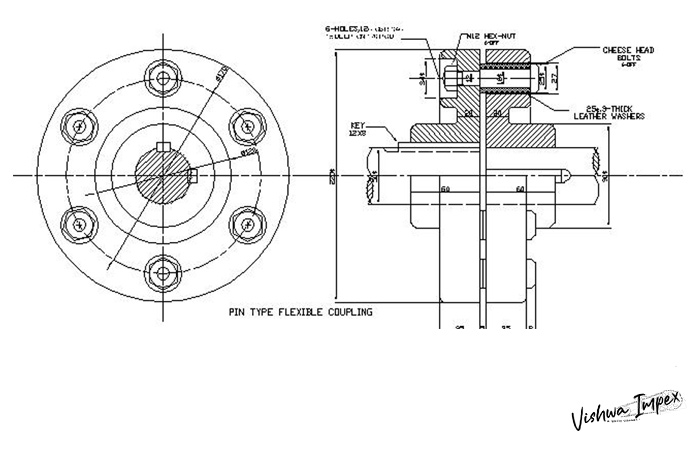

Flexible Coupling

In mechanical transmission of force from gearbox to shaft with unit, event of misalignment between the shafts to be coupled is a notable peculiarity. To alleviate the equal, rakish or mix of these two misalignment, wide reach and kinds of Flexible Couplings are being utilized. Flexible couplings are categorised into two types metallic and elastomeric. Metallic sorts utilize freely fitted parts that roll or slide against one another or, on the other hand, immobile parts that twist to take up misalignment.

Elastomeric types, then again, gain adaptability from tough, stationary, elastic or plastic components transmitting force between metallic center points.

WHY US?

◎ Fast Delivery

◎ Reliable and Flexible

◎ Minimized Assembly

◎Bigger Bore limits.

◎ Obliges Angular, Parallel and Axial Misalignment