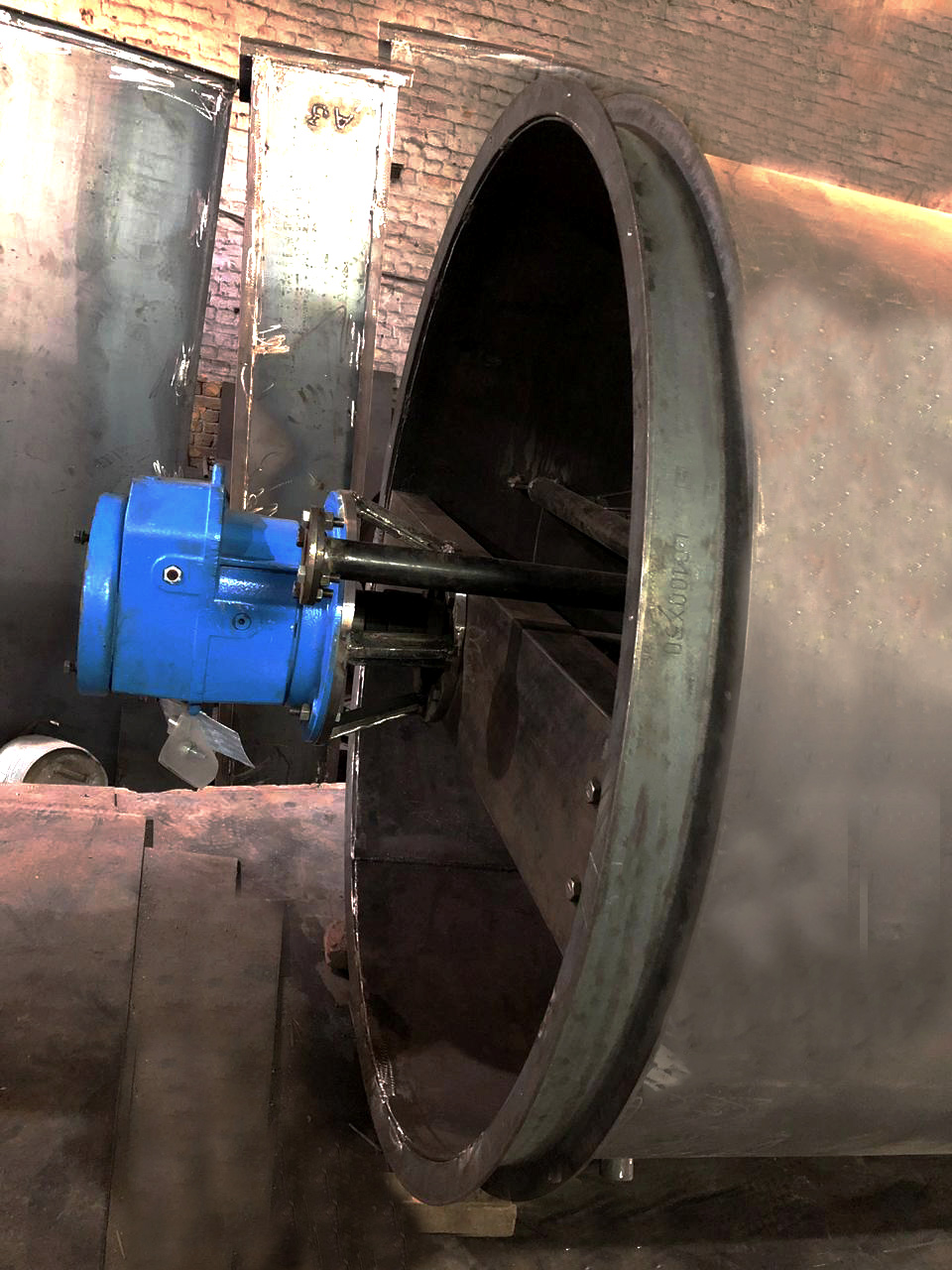

Vishwa Neutralizer is superior option for reducing concentration of free fatty acids to maximum 0.10%..

After the extraction of crude oil through mechanical screw press or solvent plant it is processed to degumming section. The 2nd step is followed by neutralization, where the vessel act as a reactor batchwise. The reaction is done with a diluted alkali solution commonly sodium hydroxide to reduce its residue soap and gums.

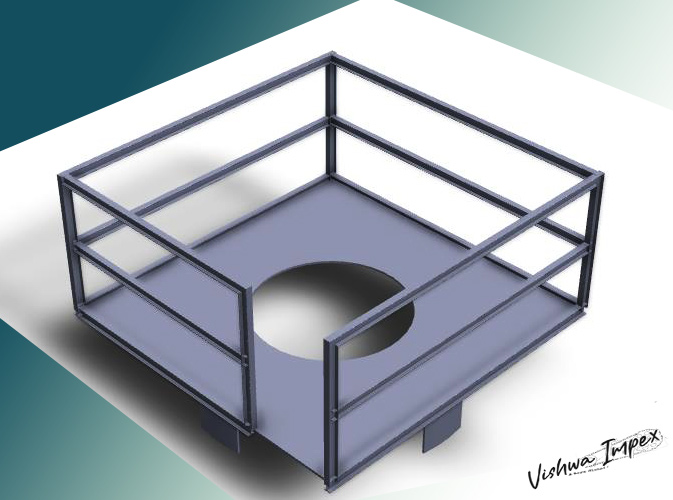

An estimation of Area is undertaken where for accurate erection of Equipment...

Consider the height and clearance you anticipate to maintain while using the steel platform. You'll want to consider worker comfort and ensure that the new platform provides adequate room for them to execute their tasks. Aesthetics may also play a role; choosing between painted finishes, anti-corrosive coatings, and galvanised steel can help you match your platform to your current aesthetic. Of course, safety should be a consideration when selecting an industrial steel platform..

We start with a basic concept, then analyse the design's practicality, adapt to a workable final design, and lastly implement in a cost-effective manner. Vishwa manufactures silos in a variety of sizes to meet our clients' needs, and we are well positioned to produce high-quality silos on time and under budget. It is preferable to create the silo tall and narrow to save space on site, but in the case of powdered product, this is required to make the steep bottom cone more controllable.

Contact Us