A coupling is a mechanism that connects two shafts at their ends in order to transmit Power. They also hep in incorporate overload protection. In the event of space constraints, to add further flexibility while transmitting power. Also, to reduce jerk loads while roation of shafts.

Couplings are categorized into two types: material flexing and mechanical flexing. Mechanical flexing connections accommodate misalignment caused by metal surface shaking, rolling, or sliding. Lubrication is required for all metal mechanical flexing connections.

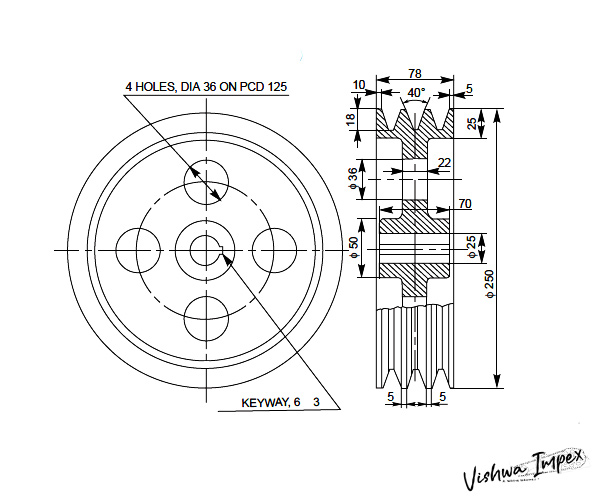

Driving Pulley are available in different sizes according to application Requirements. Custom Manufacturing is also Available.

Available In :

• Stainless Steel 304 or 316

• Cast Iron

• Mild Steel

The various Characteristics Must be considered before placing an order:

• Torque Required High Or Low

• Bore Bigger or Smaller

• Bi part Or Single

•Application Requirements