The first process in designing a Screw Conveyor is to evaluate the physical properties of the material as well as the velocity at which it will be conveyed...

A conveyor that will be utilised occasionally for two hours per day does not need to be as robustly built as one that will be used continuously twenty-four hours per day. Having the correct equipment allows your company to cut expenses while maintaining great output. We offer a wide range of solutions available to guarantee that you get the best solution possible.

Vishwa conveyers are industry leading choice with specialisation in designing product with Solidworks and Nastran analysis

Controlling the loading of the conveyor should be done with caution because it is intended to accommodate a specific maximum amount of material. There are complications. when the conveyor is loaded without the convenience of input volume controls. If the frequency of material flow is not self-regulating or cannot be self-regulated, be governed by other controls, it is recommended that a Screw Feeder be included. into the system to handle peak loads and provide a continuous, metered output supplied to the Screw Conveyor

An estimation of major quantities of material for mechnanical processing is undertaken.

The working mechanism of incline screw conveyor is quite different because each degree of inclination affects the conveyor's productivity and the amount of material that travels through it. A standard Screw Conveyor inclined 15° upward may only carry 75% of its rated horizontal capacity. At an inclination of 25°, a standard conveyor may only handle 50% of its horizontal capacity. Since, to draw the stuff more torque is required resulting in high horsepower motor due to gravtitational force.

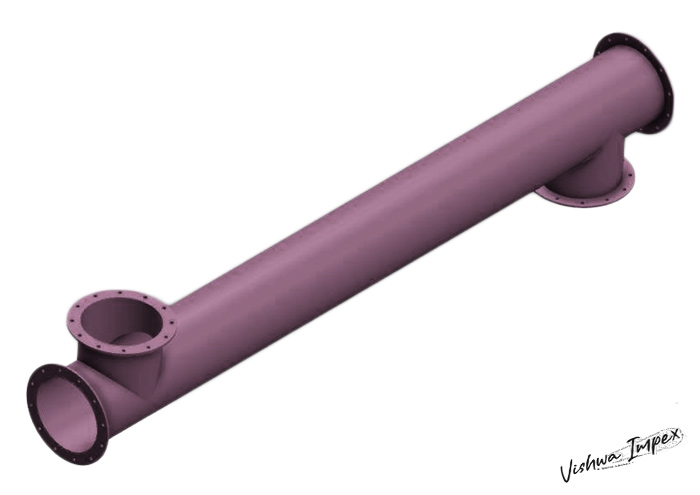

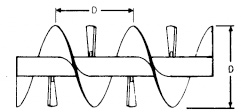

Vishwa Tubular Conveyers are made in different gauges according to application requirements

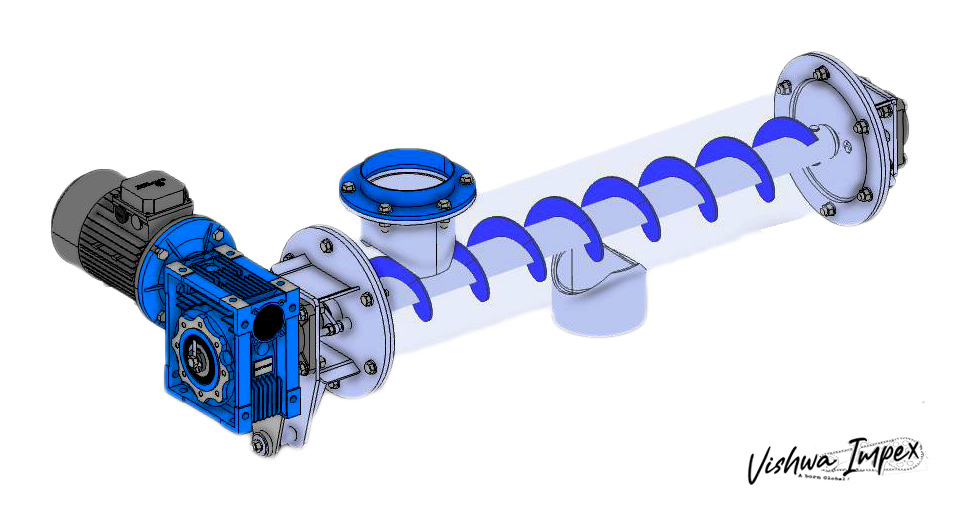

Tubular body conveyers are used to handle granule or powdery substance and is extremely adaptable for wide range of applications. It comprise of a rounded Tube furnished with no less than one channel and outlet ramble, a welded spine at each cylinder end, helicoid screw flighting welded on a middle line with a coupling shrub at each end, two end bearing congregations complete with self-changing shaft seal, various moderate holder direction relying upon the general length of the screw transport.

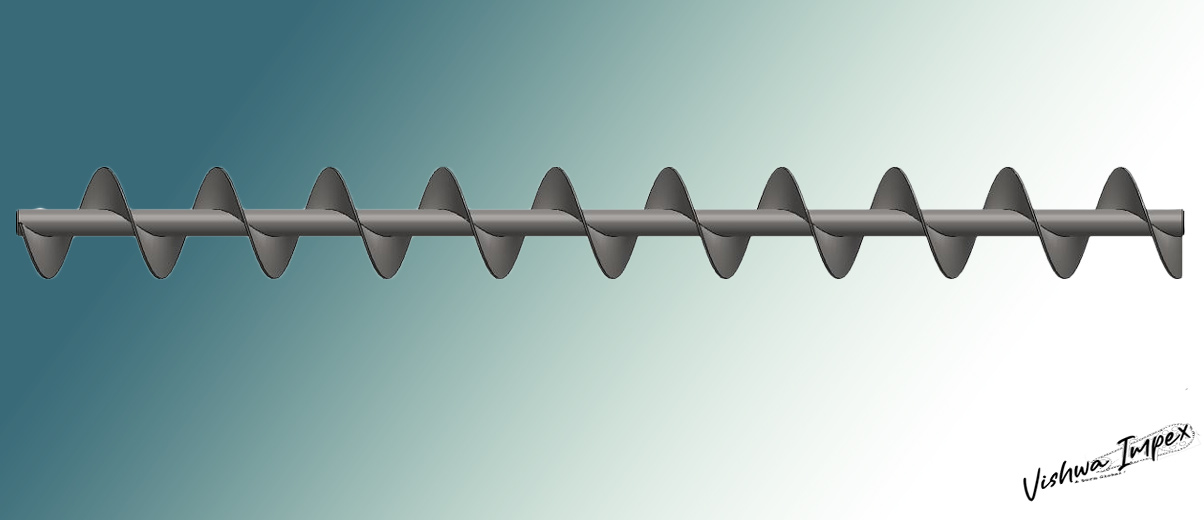

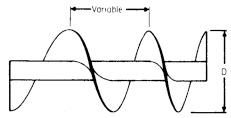

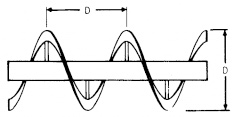

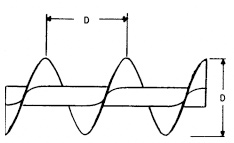

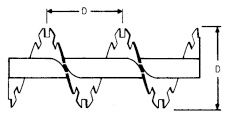

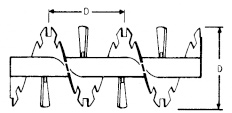

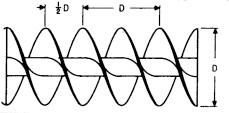

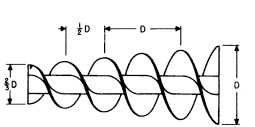

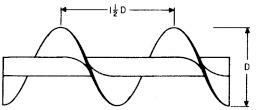

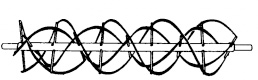

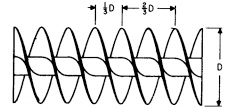

Screw Flights assembly are very important for material handling. Material properties must be analysed for adequate dimensions of screw..

Screw flights are available in right hand and left hand side. Vishwa always recommend to use standard length conveyors. All Screw Flights are manufactured with match mark and qr code for easy access to spare parts.

| Technical data | |||

|---|---|---|---|

| Material Composition | Mild Steel | Stainless Steel | Alloy Steel |

| Single Flight |  |

Variable Pitch | |

| Single Flight Ribbon Type |  |

Standard Pitch | |

| Single Flight |  |

Standard Pitch | |

| Single Cut Flight |  |

Standard Pitch | |

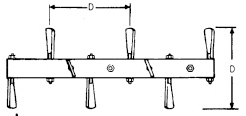

| Cut Flight with Paddle |  |

for mixing and blending of material | |

| Double Flight |  |

Standard Pitch | |

| Double Flight Tapered |  |

Standard Pitch | |

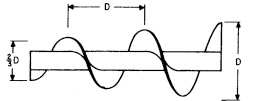

| Single Flight |  |

Long Pitch | |

| Multiple Ribbon |  |

For positive and thorough Mixing | |

| Double Flight |  |

Short Pitch | |

| Paddle Flight |  |

For cutting & breaking of material | |

| Single Flight With Paddle |  |

Standard Pitch | |

| Single Flight Tapered |  |

Standard Pitch |